Remote Reading System

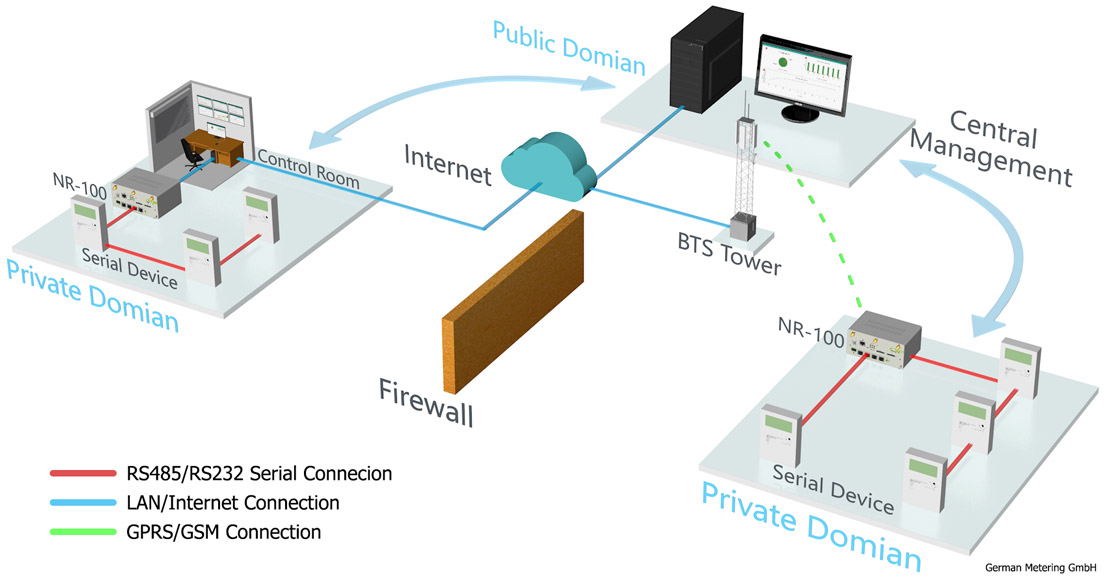

Remote Reading System is a solution that has come to help the industry to monitor, control and manage more easily and with higher accuracy. In this system, it is necessary to collect the required information such as the information of electricity, water, gas meters, sensors, etc. through a communication network such as a GPRS or a local network (LAN) and verify their accuracy and analyze them to create reports and charts. This system can be used to issue subscribers’ bills, optimization plans, etc.

One of the biggest challenges that different industries are facing today is designing an infrastructure to meet the growing industrial communication needs. Industrial networks are heterogeneous communication platforms that have evolved over time to meet the diverse needs of their users. In addition to providing a central network infrastructure, the industrial network must also support the communication needs of new equipment that is added to the network.

In the remote reading system, in addition to saving time compared to manual reading of equipment (such as meters, sensors, etc.), it helps to eliminate wrong reading errors, time-consuming follow-ups and estimated calculations. Instead, there is easy and secure access to equipment data at any time.

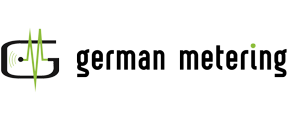

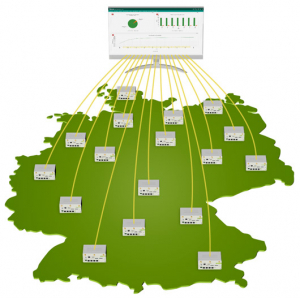

The remote reading system requires that the equipment has the ability to communicate remotely with the server (such as a smart electricity meter), or, for example, send information to the server through a modem. In this method, the equipment is connected to a modem and its communication with the server is done through the modem.

The remote reading system increases the quality of the data, and also makes it easier to analyze, as information is prepared with the data from the readings taken simultaneously. With frequent equipment data, the effects of optimizations can be evaluated, and problems can be identified much earlier, instead of only once a year.

One of the important tasks in the network is to ensure the continuous operation of the network. In an industrial environment, even a communication delay of a few seconds or a problem in any of the components of the industrial network can stop an important and vital industrial activity. Therefore, it is essential to have the right monitoring tool for the network administrator so that the current status of all network components can be monitored.

It is very important to be able to see the state of the network resource to manage the productivity of the industrial network. Network administrators can use a management dashboard that includes the following:

- Current status of equipment with the ability to sort

- Monitoring of received signal strength index

- View data records of each device

Gathered records (logs) of each device, such as connection status, antenna status, and received signal strength, can be a powerful tool to help the network manager quickly find out a problem and take corrective action.

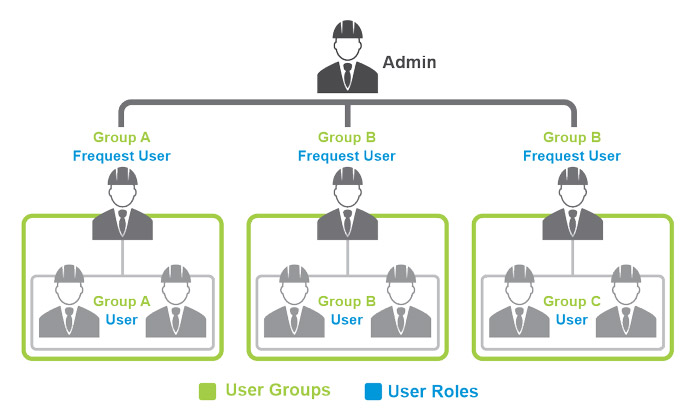

Access management based on the equipment group creates the flexibility of the equipment group according to their specifications for effective management. Using this feature, equipment can be grouped based on importance, location, type, and other characteristics. Also, a functional filter that allows network administrators to search for equipment based on equipment name, MAC and IP address, etc., makes it easy to locate equipment and take quick actions when a problem occurs. Through a good equipment management system, network administrators can control account access based on equipment groups and assign different roles to each.

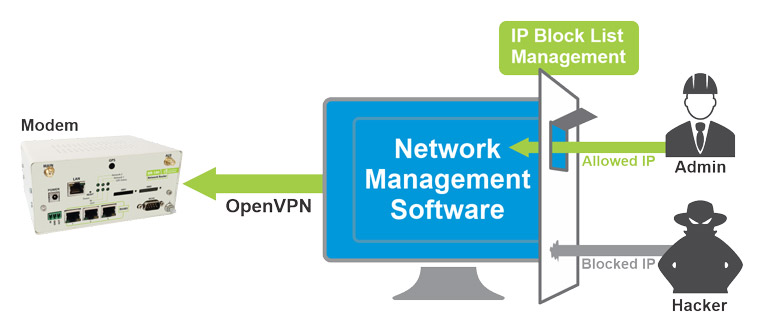

Network security is an important concern for network administrators and users. When repeated threats are made by hackers who are always developing new techniques to attack industrial networks, your network security may not be enough.

An operation such as blocking an IP address can be a very effective and fast way to deal with a known security threat from a specific IP address that blocks the source of the threat and malicious communication from the hacker. But in any case, the matter does not end here. Hackers are known for their ability to find creative ways to replicate their attacks. These cases can be dealt with by strengthening the security of the industrial network and assigning communication licenses only to approved IPs and blocking other IPs. The operation of blocking IPs is especially useful in situations where equipment on a private mobile network needs access to a public IP network. In addition, a solution that supports the OpenVPN protocol can facilitate the use of a secure communication tunnel between remote equipment and network management software.

Since mobile networks are usually embedded at the edge of the network to facilitate communication with remotely installed equipment, the network management tool should have the ability to remotely configure the equipment, restart, import and export settings, update the firmware and include functions such as updating status and displaying equipment records.