Energy Calculation

1. Energy Calculation

As consumers, when we look at the amount of energy consumed and think about saving it, we naturally think of large appliances such as refrigerators, air conditioners, fireplaces, swimming pools, etc. In the company, we think about cooling and heating systems, lights, desktop computers and equipment. There are also smaller devices that work most of the day and may consume a large amount of energy.

Reducing energy consumption is the most effective way to prevent climate change and global warming as well as environmental pollution. The saved energy is the cheapest source of energy! And it is much cheaper than building new power plants. With the help of energy calculation and its control, we can achieve this important goal.

Unit of energy consumption (joule)

Joule is a term used to measure energy as a standard unit of measurement. In the electricity industry, consumption is usually measured in kilowatt hours (kWh) and its relationship with joules is 1kWh=3.6MJ. In other energy sources, which are water and gas, the unit of consumption is in terms of volume, which are usually measured in cubic meters, cubic feet, liters and gallons. For natural gas as a source of energy, 1m3=3.7MJ.

| Energy Use | Energy Use in Joules | |

| Electricity | 1 kWh | 3,600,000 J |

| Gas | 1 m3 | 3,700,000 J |

Energy consumption in countries

Energy consumption is influenced by many social and economic factors and drivers. Especially in less developed countries, increasing population as well as increasing GDP may lead to a significant increase in energy consumption. The world population is expected to reach more than 9 billion people in the next 20 years.

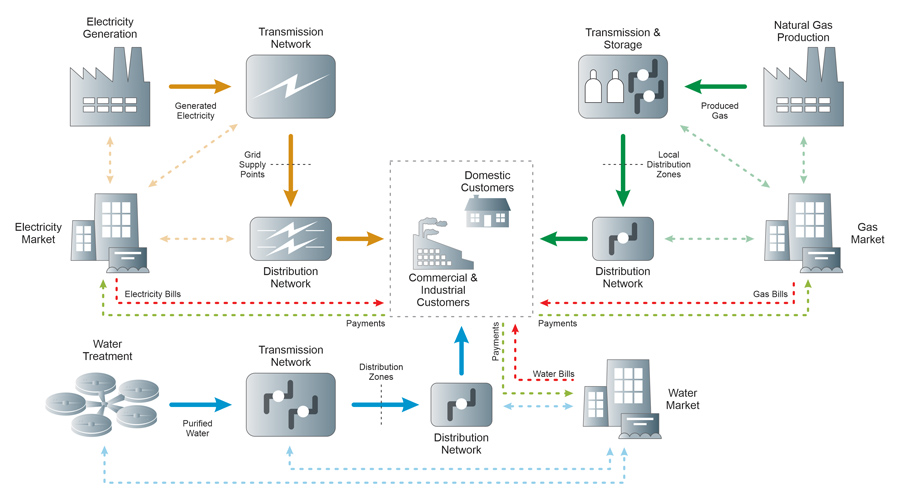

Take a look at the performance of the energy market. The figure below provides a simplified view of the energy market:

Electricity Market

Electricity is produced in power plants and transmitted in the high voltage transmission network. The transmission network feeds the low voltage distribution network through a set of connection points called network supply points. The distribution network delivers electricity to the location of domestic, commercial and industrial customers. The electricity supplier is responsible for buying electricity from the producer and selling it to customers and issuing electricity bills. The electricity system operator (the national grid) is responsible for balancing the system (handling the amount of electricity produced and the total demand of consumers).

Gas Market

After extraction and processing in the production units, the gas enters the high pressure transmission system. It is transferred to a number of low pressure distribution networks through the transmission system and then delivered to the residential, commercial and industrial customers through the distribution network. Suppliers are responsible for selling gas to customers and issuing invoices for gas consumption. The gas network operator (the national grid) is responsible for balancing the network on a daily basis, i.e., ensuring that the flow of gas into the network is balanced with the output from the network.

Water Market

After the water is taken from the available sources and during the purification process in the treatment plants, it enters the transmission system. It is transferred to a number of distribution networks through the transmission pipeline and then delivered to the domestic, commercial and industrial customers through the distribution network. Suppliers are responsible for selling water to customers and issuing water bills. Subscribers may have their own water wells or draw from surface water sources, for these subscribers, appropriate water meters should be installed and invoices should be issued for them according to their usage.

2. Industrial Area Energy Calculation

The importance of energy calculation and its management in industrial area:

- It helps to reduce greenhouse gas emissions and global warming

- It reduces dependence on fossil fuels

- Reduces energy-related costs while helping to grow future investment opportunities

The industry sector is one of the energy-intensive areas with high energy consumption and accounts for about 70% of global greenhouse gas emissions, which is one of the main factors of ecosystem change. With climate change plaguing societies around the world, the importance of energy management in industrial area has become more apparent than ever.

There are countless ways to reduce energy consumption and thus reduce environmental pollution, but energy calculation in industrial area is one of the most sustainable long-term solutions.

Reduce greenhouse gas emissions and global warming

Whenever energy is consumed or produced by fossil fuels, greenhouse gases (mainly carbon dioxide) are released into the atmosphere, which in turn causes global warming.

Every year, scientists publish more information about global warming and its devastating effect on people and the planet earth. Decrease in water reserves, disappearance of natural glaciers, rise in sea level, increase in floods and land erosion, heat waves, decrease in agricultural production, disturbance in habitats, drought, spread of insects, fire and increase in the spread of epidemic diseases from the consequences of warming are universal. If we fail to reduce our greenhouse gas emissions, scientists believe global warming could kill 250,000 people worldwide every year and push 100 million people into poverty within 10 years. Energy management in industrial area is a global need as it reduces the effects of global warming.

It reduces dependence on fossil fuels

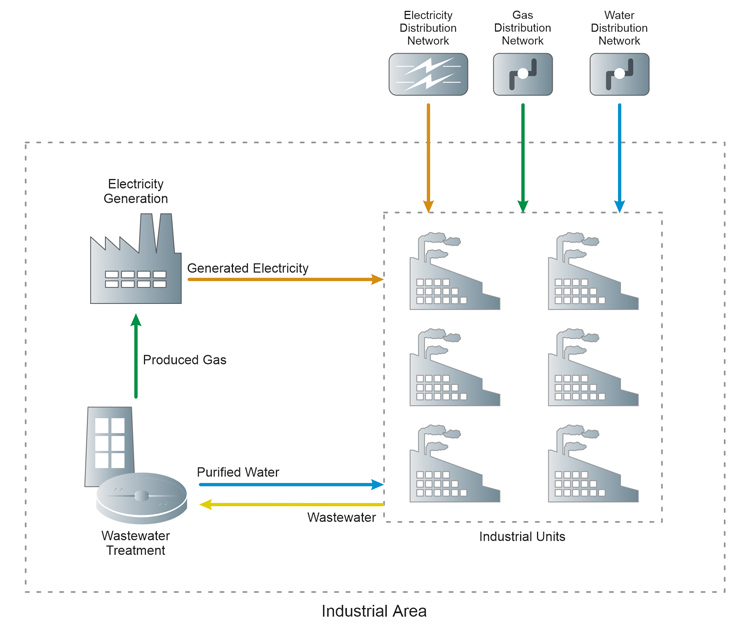

Consider an industrial town that treats 1,000 cubic meters of wastewater daily using the activated sludge method. Wastewater contains biodegradable materials that are first treated with anaerobic bacteria. The produced methane gas is collected and burned to generate electricity. In this way, industrial estates generate their own electricity and meet their local energy needs while reducing dependence on non-renewable energy sources such as fossil fuels.

Reduce energy-related costs while capitalizing on future growth opportunities

One of the pillars of energy management is energy saving. If industrial estates rely on renewable energy, it not only provides a sustainable source of energy, but also makes the industrial area less dependent on power companies. This is where energy consumption monitoring in industrial area and calculating the energy used becomes important. With the help of these calculations, in addition to estimating consumption and finding solutions to reduce energy consumption, we can try to achieve important goals such as reducing greenhouse gas emission and ensuring the future health of the earth. With the help of installing remote reading modems for measuring equipment such as electricity, water and gas meters, in addition to monitoring the consumption status of industries and issuing invoices for them, we can also control the status of energy consumption in real time.

3. Building Energy Management Systems (BEMS)

Buildings have become an integral part of the landscape of cities. The purposes of these buildings can be from residential to commercial or institutional, and like any infrastructure, these buildings rely on energy to function properly. Energy consumption in buildings constitutes about 40% of the total energy consumption in Europe, of which 30% is wasted. This makes the need for smart systems that can store part of that energy in buildings even more vital.

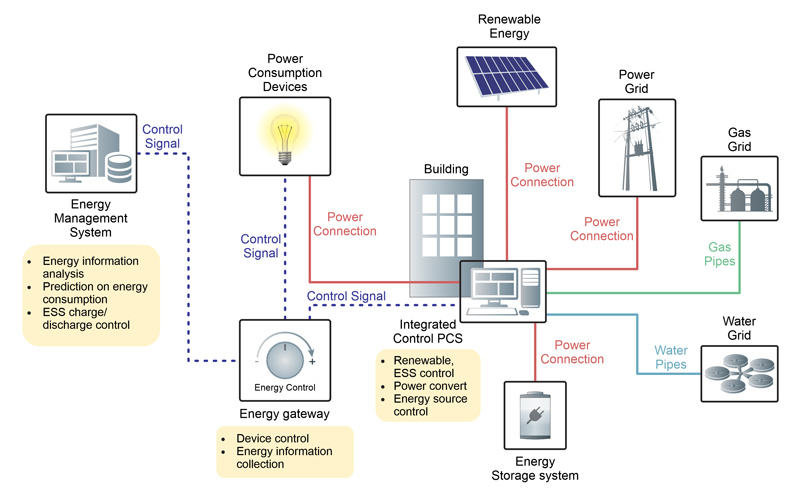

Building Energy Management Systems (BEMS) for better energy efficiency

A building has various devices or applications that require different types of energy to operate, and for a better use of energy, this wide range of energy consumers must be integrated into a system, which not only collects information about energy consumption, but also gives the building manager the ability to control them. This system called Building Energy Management Systems, also known as BEMS.

Some of the most common applications used in BEMS for energy optimization include heating, ventilation, air conditioning (HVAC), lighting, landscaping, etc. These are usually the primary aspects of a building whose energy consumption should be managed.

Building energy management systems (BEMS)

Building Energy Management Systems (BEMS) are integrated computer systems for monitoring and controlling energy-related building service facilities and equipment, such as heating, ventilation and air conditioning (HVAC), lighting, power systems, etc.

Building energy management systems (BEMS) are sometimes used interchangeably with building management systems (BMS), however, more specifically, building management systems can be used to monitor and control a wide variety of building systems, from including fire, smoke and alarm detection, motion detectors, CCTV, security and access control, elevators, etc. Building energy management systems are specifically related to energy-related systems.

BEMS provides remote monitoring and integrated control of a wide range of connected systems, allowing monitoring of operating modes, energy consumption, environmental conditions, etc., and allowing operating hours, set points, etc. adjust for optimization. Estimates of the amount of savings that can be achieved by BEMS range from 10% to 25%, so that the reduction in energy consumption does not negatively affect comfort and performance.

The best solution is to consider all factors

The first step in building energy management is to know exactly how much energy is used and where. With this information in hand, areas for improvement can be highlighted, which in turn helps to make the system more efficient and ultimately save energy.

Growth in technological advancement has made building energy management systems a critical component for managing energy demand, especially on large construction sites. They can effectively control 84% of the building’s energy consumption. Commercial and residential buildings produce a significant share of greenhouse gases. Making buildings more efficient is an important opportunity to contribute to a lower energy future as well as a future with less environmental impact.

For example, BEMS may dim or turn off lights in certain areas, raise or lower temperature set points. BEMS are also capable of monitoring, collecting and processing data at the base level to inform logically controlled responses.

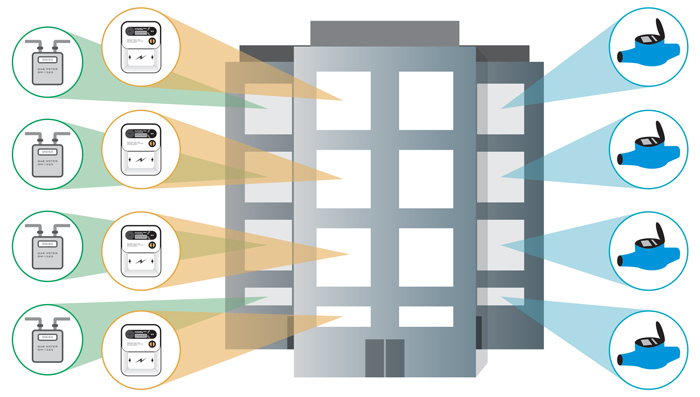

4. Separation of Electricity, Water and Gas Meters

In many complexes, buildings, centers, etc., there is a need to separate electricity, water and gas meters for subscribers and use them separately, because if a meter is used jointly, the consumption is divided according to the number of people in each unit or the number of units is necessary, but it is not fair, because the amount of consumption is definitely not distributed fairly.

In order to separate the meters, some things must be considered first. Basically, there are two solutions for this purpose. In the first solution, a separate meter is installed for each customer, and it should be considered that there is a separate electric wire as well as a separate water and gas pipe for each unit. Otherwise, due to the high cost of separate piping for each unit and the damage caused, we will look for the second solution.

The second solution is to install an electricity meter, a water meter and a gas meter for the subscriber at the entrance of each unit and manage the bills of the units by using a software.

5. Electricity Billing

The electricity supplier company announces the billing period, meter reading date, bill date and payment due date to its subscribers in one calendar month and sends the issued invoice to each subscriber. These bills are prepared based on meter readings.

Energy calculation is simple. The unit of electrical energy is kilowatt hours (kWh), which is obtained by multiplying electricity consumption (in kilowatts) by the number of hours of electricity consumption per day. Multiply this by the cost per kWh and you will have the total cost of energy for the day.

- Cd = (p/1000) * t * c

- Cm = Cd * d

- Cd: total energy cost per day

- Cm: total energy cost per month

- p: power in watts

- t: working hours per day

- c: cost per kWh

- d: The number of days of the month

Contrary to the simple appearance, in reality if we want to measure the actual power consumption of a device, there are variables that we must consider:

- Electricity rates are variable.They differ based on the hours of use and high consumption of the subscriber.

- Real consumption of the device

- Exact working hours per day

- Different functional modes (off mode, standby mode, working mode, etc.)

Different rates of energy

Energy costs are not fixed. For example, in residential use, the more you use, the more you pay and it increases exponentially. During peak hours, the rates are higher and during other hours, the rates are lower. In the calculations, we should calculate the costs with the highest usage rate. This is the amount we pay for each kWh we use or save from our current consumption. This is the amount we can save by reducing consumption.

6. Water Billing

Water companies use different units to measure water consumption. The most common units are cubic meters, liters, cubic feet, and gallons.

What does use mean? For example, if an person consumes about 40 liters of water per day, this means that a family of four will consume about 160 liters in one day and 4,800 liters in a 30-day period. Usage rates vary greatly in different parts of the country, mostly due to differences in weather patterns. For example, water consumption is higher in drier areas than in wet areas.

What costs are included?

Water companies must charge subscribers for the construction and maintenance of infrastructure. Water storage tanks, treatment plants and underground pipes, as well as paying the salaries of the workers who provide us with water services day and night, are all costs that water companies pay. There are a wide variety of rate structures used to bill customers.

Types of rates

- Fixed cost, all customers receive the same bill of water consumed. Fixed charges are the simplest type of rate structure and are rarely used today.

- Uniform rate, for all measured units of water consumption throughout the year, has a fixed price per unit. It differs from fixed cost in that it requires metering services (meters). Some water companies charge different rates for different user groups, such as residential households with one rate and industrial users with a different rate.

- Increasing block rate, the unit price of each subsequent block of use is calculated at a higher unit rate than the previous block(s). Block rate increases are designed to promote conservation and are often found in urban areas and areas with limited water resources.

- Block rate reduction is the opposite of block rate increase where the unit price of each subsequent user block is charged at a lower unit rate than the previous block(s). These rate structures are popular in rural areas serving large agricultural populations or areas with large users such as heavy industry and where water is abundant.

- Seasonal rates are rates that cover a specific period of time. They are designed to encourage conservation during periods of peak use. Examples of seasonal rates may have lower rates for the winter season and higher rates for the summer season due to increased water consumption associated with watering landscaping and outdoor activities.

- Drought rates are similar to seasonal rates, but instead of applying higher rates over an entire time period, rates are adjusted based on the level of drought in the area. Higher levels of drought lead to higher water prices to encourage conservation.

- Rate based on water budget, households are given a “water budget” based on the anticipated needs of that household or based on the number of people living in the house or the size of the property. Users are charged a set rate for usage within their budget, and a higher rate for usage over their limit. The goal is to encourage efficient use of water for each subscriber.

7. Gas Billing

Issuing a bill and receiving the cost of gas consumed from each subscriber is very important for gas distribution companies. Continuity of the companies’ work as well as compliance with consumption patterns by subscribers are among the results of this. One of the problems faced by gas supply companies is the issuance of correct bills, which is the result of correct measurement and accurate use of formulas and tariffs.

Debit/credit information is included in the calculation and issuance of subscribers’ bills. Information such as types of tariffs, tariff rates, tariff coefficients and special subscriber discounts are also required. All of this information is used to calculate and issue subscribers’ bills.

By changing the temperature and pressure of the gas, its physical properties such as density have changed and this complicates the exact calculation of gas consumption. In the pressure reducing stations, with the help of installed correctors and sensors, and measuring the following parameters, the amount of gas consumption can be calculated as accurately as possible:

- Volume of passing gas

- Temperature

- Pressure

In home applications, due to the limitations and lack of cost-effectiveness of installing a pressure sensor in the gas passage, smart meters try to measure the following parameters and make calculations, to reach the most accurate number of gas consumption:

- Volume of passing gas

- Temperature

Gas meter reading is done both in person and remotely. In the face-to-face method, the reading agent needs to go to the meter, but in the remote reading method, gas meter information is sent to the server with the help of a modem. After the reading operation, according to the amount of gas consumed by the subscriber, calculations are made for him according to the available formulas and a bill is issued to the subscriber.